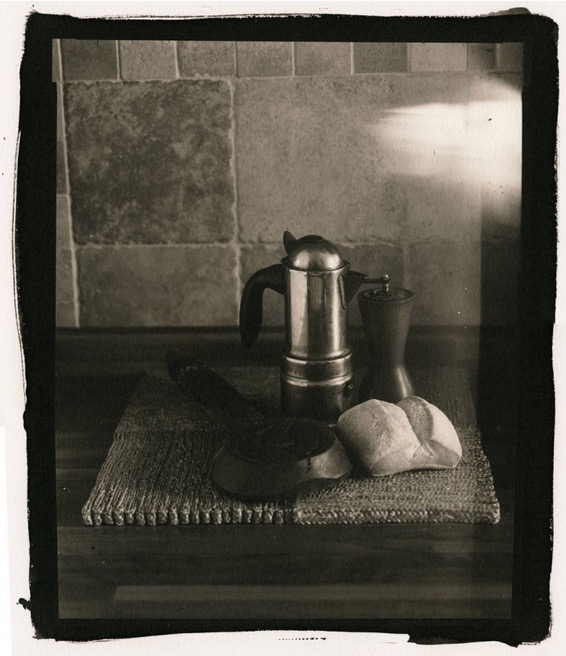

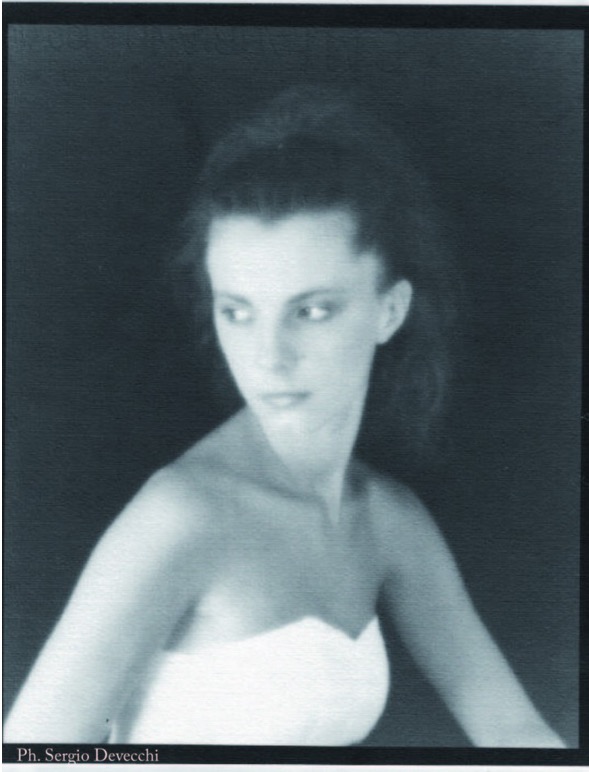

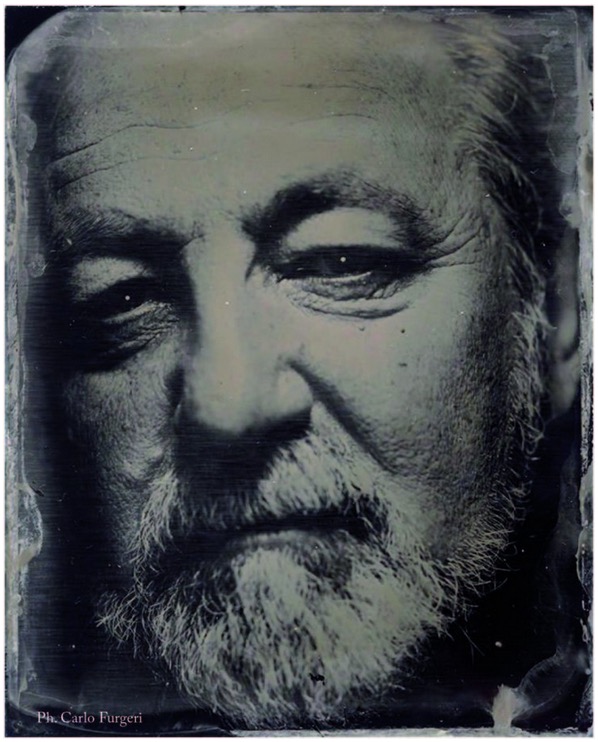

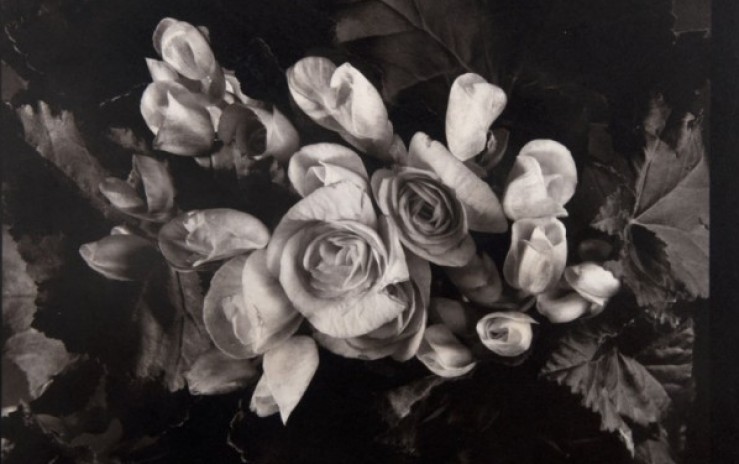

Platinum print – Palladium print

Platinotype is one of the most noble and expensive processes. Its main features are long tonal scale, especially in the shadows, deep dark values, almost absolute persistence over time: the metallic molecules trapped in the paper will gone only with the paper itself. No risks at all for fading.

The process in brief

In dimmed light, ferric oxalate and Platinum (Pt) and/or Palladium (Pd) salts are added in equal amount to obtain the sensitizing agent, used to coat the paper with a hake brush or a rod.

In dimmed light, ferric oxalate and Platinum (Pt) and/or Palladium (Pd) salts are added in equal amount to obtain the sensitizing agent, used to coat the paper with a hake brush or a rod.

Once dried, a negative is put in contact and exposed to UV light.

The right exposure produces a “hint” of image. The developer (potassium oxalate or ammonium citrate) is quickly poured over the exposed paper put into a tray, with instant full developing of the image. Baths with EDTA and/or sodium sulphite allow the removal of the unexposed sensitizer, so clearing the highlights. After final wash in water, the paper is hang on a line and dried.

How it works

The action of light changes Ferric(III) oxalate to Ferrous(II) oxalate. The goal of the development process, is to take advantage from the tendency of Fe(II) to go back to Fe(III), acting as a reducer itself over the Pd/Pt salt and making it precipitate into the paper’s fibres.

Chemicals and recipes

For the coating solution, almost equal parts of sensitizer (ferric oxalate) and metal salts are combined. In addition, a restrainer (an oxidizer) can be added to control the final contrast.

Sensitizer, A-B-C formula – A and B compound: the light trigger (Ferric oxalate)

A 27% solution of Ferric oxalate is the light triggering agent: the A part of your working solution.

You have two choices. You can obtain it powdered (long lasting), or diluted (which must be kept at low temperature (4°C) in a fridge to obtain the longer durability). The powder can be stored for an almost unlimited time.

To dissolve: warm up the water (use only demineralized water) to 110-120°F (40-48°C). Do not pass the 122°F or 50°C. Add a pinch (1 gr for 50-60 ml of solution) of oxalic acid and 2 drops of peroxide hydrogen (≥80 volumes). Add all the powder in the right amount, Stir thoroughly and let it age for at least an hour.

At the end of the process you have a deep yellow-green liquid; if you see turbidity, it can be filtered with paper, to obtain a clear solution.

If you buy instead the solution, it will not last forever. Average duration is 6 months, if keeped in fridge, at 4°C.

You will know that your fe-ox is old when the prints get a yellow discoloration visible in the highlights. Look at the bottle, if you see some precipitate-turbidity, you will probably rescue the solution by adding oxalic acid and oxygen peroxide, and your ferrous oxalate will turn back in its soluble, ferric state.

To achieve contrast control you must introduce an oxidizer, the B part of your working solution.

The oxidizer acts as a “restrainer” in the reduction of platinum or palladium metal salts to their elemental form.

The commonest method is the A+B or the Ratio method, where potassium chlorate is added to Ferric oxalate in different percentages; the Exposure Scale (ES) can be modified of ±0.9 units. The solution B is also a 27% Ferric oxalate solution, but potassium chlorate (the oxidizer) at 0,3 (solution B#Pt for platinum) or 0,6 % concentration (solution B#Pl, for potassium) is added. By varying the relative amount of A and B, you obtain a solution ranging from no potassium chlorate (A only) to 0,6% (B#2, only). When you print with a mix of platinum and palladium, use the B#Pd solution. High concentrations of chlorate result in flocculation and uneven (grainy) results, and the increase in contrast, as a general rule, means the shrinking of tonal scale: this is another reason to learn to produce good negatives instead of adjust weak prints.

| Platinum/Palladium part A (ferric oxalate) | |

| 55 ml | distilled water |

| 16 g | ferric oxalate |

| 1g | oxalic acid |

| Platinum/Palladium part B#pt (ferric oxalate and potassium chlorate as a contrast control) for Platinum | |

| 55 ml | distilled water |

| 16 g | ferric oxalate |

| 0.3 g | potassium chlorate |

| 1g | oxalic acid |

| Platinum/Palladium part B#Pd (ferric oxalate and potassium chlorate as a contrast control) for Palladium or for mix of Palladium and Platinum |

| 55 ml distilled water |

| 16 g ferric oxalate |

| 0.6 g potassium chlorate |

| 1g oxalic acid |

Sensitizer, A-B-C formula – C compound: the precipitating agent. Platinum or Palladium

Platinum (Pt) or Palladium (Pd) are used in the sensitizer as salt. The historical salt is potassium chloroplatinite, which today is more accurately named potassium tetrachloroplatinate(II), formula K2PtCl4. Palladium salt is Palladium Chloride, PdCl2 plus NaCl. Both are used in water solution at 15% or 20%.

| 15% tetrachloropalladite | |

|

55 ml |

distilled water |

|

5 g |

palladium chloride |

|

3,5 g |

sodium chloride |

| 20% potassium chloroplatinate | |

|

50 ml |

distilled water |

|

10 g |

potassium chloroplatinate |

Developer

There are two main developers for platinotype: Potassium oxalate and ammonium citrate, which can give different results.

Potassium oxalate

It is the commonest and traditional developer for platinum print. It is used as a saturated solution, (35%). Be aware that it is toxic: it is safer to work in well ventilated areas and to wear gloves. It gives warm tones, from reddish to green-reddish brown. The darker values are rich and deep.

350 g potassium oxalate powder

1000 ml distilled water

You can prepare adding the powder to distilled water in a glass or plastic bottle with plastic cap (avoid metallic caps!). Shake vigorously.

You can use it cool or heated. When warm, tones are warmer too.

Ammonium citrate developer

Safer than potassium oxalate, its hue ranges from ochre-brown to cool brown, giving also black-and-white tones when used with platinum. The powder dissolves easily in water.

250 g ammonium citrate

1000 ml distilled water

Step by step

The Negative

Platinotype, like other alternative techniques, exhibit a specific sensitivity to UV light, preventing the use of enlargers, at least with current technology. Only contact printing is available and if some enlargement is need from the original negative, you must obtain enlarged negative.

The “ideal” negative for pure palladium print should have Density Range of 1.6, while Platinum or Pd/Pd mix print well 1.4. To say it in other words, a negative printable with grade two silver paper is too weak, and can be good if a grade zero is required. When the negative has lower DR, you must raise the contrast of your sensitizer in some manner (see further). The oxidizers used to enhance contrast induce grainy textures to the final print, so when you can, work on your negative to obtain the best one for this method.

The Paper

Cut the desired size. Take your sheet of paper, and find the right side.

With a pencil, mark the negative area.

Ferric oxalate and and ferric oxalate plus contrast control

The suggested total amount of ferric oxalate and the relative percentage of A and B can be decided upon the following reference chart. The amount is set up in drops, referring to common plastic droppers: as an average, 20 drops equals 1 ml.

The more the chlorate, used to achieve more contrast, the more grainy the appearance (due to flocculation and microscopic uneven mottled appearance) and the longer the exposure.

Palladium gives warm brown hues, while platinum gives black, neutral tones. The greater the platinum, the neutral the tones. Pure platinum is hardly used for two reasons: 1) Pure platinum salts are not fully responsive to a ferric oxalate sensitizer; adding at least one drop of palladium to platinum improves the reliability of the process. 2) 10-20% of palladium doesn’t affect too much the result if compared to pure platinum, and is cheaper.

Many other variables affect the tone (the developer is the most relevant issue, tones change also with repeated use of the developer and with different papers).

| Negative contrast | Drops for 4X5”(10X12 cm) | Drops for 5X7”(13X18 cm) | Drops for 8X10”(20X25 cm) |

| Very Contrasty | |||

| A | 6 | 12 | 24 |

| B | 0 | 0 | 0 |

| Pt and or Pd | 6 | 12 | 24 |

| Contrasty | |||

| A | 5 | 10 | 20 |

| B | 1 | 2 | 4 |

| Pt/Pd 50% | 3 + 3 | 6+6 | 12 + 12 |

| High Medium | |||

| A | 4 | 8 | 16 |

| B | 2 | 4 | 8 |

| Pt/Pd 50% | 3 + 3 | 6+6 | 12 + 12 |

| Medium | |||

| A | 3 | 6 | 12 |

| B | 3 | 6 | 12 |

| Pt/Pd 50% | 3 + 3 | 6+6 | 12 + 12 |

| Low Medium | |||

| A | 2 | 4 | 8 |

| B | 4 | 8 | 16 |

| Pt/Pd 50% | 3 + 3 | 6+6 | 12 + 12 |

| Thin | |||

| A | 1 | 2 | 4 |

| B | 5 | 10 | 20 |

| Pt/Pd 50% | 3 + 3 | 6+6 | 12 + 12 |

| Very thin | |||

| A | 0 | 0 | 0 |

| B | 6 | 12 | 24 |

| Pt/Pd 50% | 3 + 3 | 6+6 | 12 + 12 |

Blend the chemicals

Dim the light. Avoid tungsten and cold compact fluorescent light (CFL) because they emit a certain degree of UV light (which can be relevant for some CFL). You should be able to clearly see what you are doing.

Put the decided number of drops of ferric oxalate, contrast agent, palladium and/or platinum, in glasses with short barrel, mix well by turning the glass in your hand, as you are going to taste a great wine, pour the sensitizer within the printing area.

Coat the paper with even brushes and let it dry. Expose it in a brief time (hours): it is not intended to be stored for long periods.

Expose the sensitized sheet

Put the sheet in your contact frame or over a flat surface and put your negative, right reading (emulsion down, mirroring surface of the film up), and close the frame or cover with a glass.

Put it under the light (sun, UV bulbs) for the right time. If you can do it without losing the register, inspect the print until you see a hint of image. As a general rule, if blacks are almost black in the print before development, it is overexposed. If it happens, try to develop in water or simply make another print.

Develop the exposed paper

Put the sheet in a clean tray, which you will label and set apart for platinum print only, to avoid contaminations with other metals from other procedures.

Put the developer in a glass or plastic container with large mouth: it is important to provide a quick, almost immediate coverage when pouring. Pour quickly the developer over the paper and the resulting image will appear almost instantaneously. Whatever the chemical, in a few seconds the development is completed and the print is no longer needed in the developer. Platinum printing cannot be overdeveloped. Recollect the developer in the container for a new print.

Don’t throw it. It improves with age.

Both need to be replenished. Potassium oxalate is used in a sovrasaturated state, so it is easy to find the right amout: after filling the bottle with distilled water, add powder enough to see that no more will further dissolve. For ammonium citrate prepare some solution and add to the old.

Potassium Oxalate will form black crystals that in time form a sludge, which can be filtered with a strainer. Ammonium citrate will form a dark precipitate, ready to go back in suspension if shaken: it too can be filtered with a line cloth or a coffee filter, but is harmless.

Warm or cool developer: which one?

Raising the temperature of the developer affects the hue and tone of the final print, which become warmer. When we refer to hot developer, it means 110°-180°F (40°-80°C). Room-temperature developers have advantages over hot developers that are ease of use and lower volatility, so they are less toxic. Ammonium citrate shows the most dramatic effects, being cool or warm if cold or hot. Potassium oxalate is warm at any temperature, but much warmer if heated very much (180°F).

Clearing baths

Traditional clearing agent since the works of Pizzighelli and Hüble was hydrochloric acid, and it has been the recommended agent over years. However some bleaching does occur, making palladium prints grainier (by causing the palladium deposit less even), and warmer (by removing density from the shadows). Non bleaching agents are preferred, such as EDTA (ethylenediaminetetraacetate) and Sodium sulphite.

EDTA is the agent of choice. It exists in two forms: disodium EDTA and tetrasodium EDTA.

You must use a 3%to 5% solution in distilled water: add one tablespoon for one liter of distilled water. You can make it in the tray, because it dissolves easily. Use bare hands, it is safe. The clearing strength is better for disodium which is more acidic. If you work only with tetrasodium EDTA, you can substitute the second bath with a hypoclearing agent, that is sodium sulphite at 4% or Hypo clearing agent like Kodak Hypo or Ilford WashAid (basically, sodium sulphite with some additives). To make sodium sulphite at roughly 4%, one liberal tablespoon is added to one liter of distilled water.

Without being compulsive, the preferred sequence could be the following:

Clearing sequence

Disodium EDTA (5%) 10 min

(Tap water: 1/2 min)

Hypo Clearing Agent 10 min

(Tap water: 1/2 min)

Tetrasodium EDTA (5%) 10 min

Final wash in running water, at least 30 min

Clearing agents are collected and reused, with time they become yellow (particularly the first bath) because the sensitizer comes up in solution from the prints. When exhausted (1 liter can clear 8 – 12 prints 8X10), don’t replenish: throw out and make up a new solution.

Sodium sulphite over dresses or things, when dried, leaves a rough white spot, easily washed with water, but is harmless.

Final wash

Now you can work with all the light you want. In the last tray, wash the print in running water for a generous time, 20-30 minutes. Even if you think that the print is OK, you must watch with a good light a completely dried paper before judge the result, because of a consistent dry-down-effect, which changes tones and contrast. If you want to repeat the print in the same session, you can force the drying process to obtain information for your next print.

If you have enough time, hang up the print on a line and let it dry.

Ziatype beginners kit

Ziatype Ziatype Beginner kit (Kit09) Kit contents Sensitizing: Ammonium Ferric Oxalate sol.A 25ml Ammonium Ferric Oxalate contrast sol.B

Wet plate Collodion-formulating Poe Boy

Collodion process-Poe Boy formula (No ether/No cadmium) The procedure for the collodion “poe boy”, or “poor boy” as some say, is interesting for it does

Wet plate Collodion-Old Work-Horse process

Old Work-Horse for positive process 1°- Collodion solution (part A) pour 220 ml plain collodion into a 500 ml beaker slowly, add 140 ml ether