Cyanotype procedure

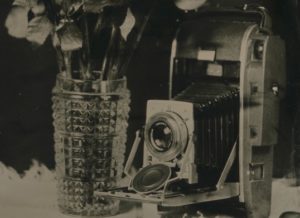

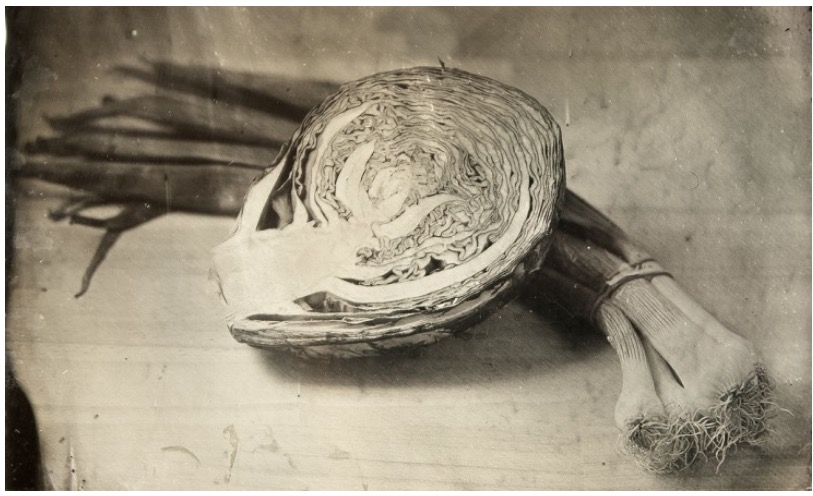

Cyanotype is a contact printing technique, which requires UV rays and a negative image of the same size as the final one.

In this printing process, dated from the middle of the 19th century, the sensitive agent is a trivalent iron salt. Trivalent iron salts are the key compounds of other printing techniques such as Platinum, Palladium, and the Van Dyke Brown print. Through the exposure to UV light, the trivalent iron is reduced to bivalent iron, which can reduce other compounds that it comes into contact with.

In the case of Cyanotype the compounds that come into play are: ferric ammonium citrate (the green one) and potassium ferricyanide.

Exposure to light forms ferric ferrocyanide (Prussian blue) which stays caught in-between the paper fibers and creates the image. The image we obtain is very stable, but could deteriorate in the presence of alkaline substances. The image could also fade if exposed to an excess of direct sunlight; in this case you can restore it by keeping it in a dark environment for a few days.

Exposure to light forms ferric ferrocyanide (Prussian blue) which stays caught in-between the paper fibers and creates the image. The image we obtain is very stable, but could deteriorate in the presence of alkaline substances. The image could also fade if exposed to an excess of direct sunlight; in this case you can restore it by keeping it in a dark environment for a few days.

Cyanotype prints can be made on whichever surface (fabric, paper, wood).

Sensitized paper can not be stored, it must be used immediately. The drying phase can be accelerated using a hair-dryer on a tepid setting.

The time of exposure varies depending on the UV light’s power and the distance from the paper’s surface.

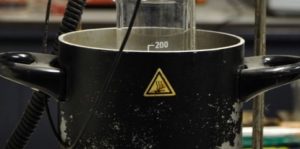

A 100W light, placed at a 30cm average distance, can use from 30 to 60 minutes time.

There are no developing or fixing phase. A meticulous wash under running water is sufficient to obtain the final print.

The necessary material is easy to find. You don’t even need the safe light; it is enough that you avoid the exposition to the light from energy saving or florescent lamps. These are two types of light which could emit UV radiation. It would be best to work with a press, but as well you may use an equivalent equipment.

To the advantage of the beginner a kit is available. See “kit section” on our website.

There are two methods for the cyanotype procedure. The old, traditional one, introduce by Sir J. Heschel in 1842, extremely simple, which consists of diluting ferric ammonium citrate and potassium ferricyanide as follows, to form two solutions:

Solution A

12 g ferric ammonium citrate in 50ml water (20 parts to 100 parts of water)

Solution B

8 g potassium ferricyanide in 50 ml water (16 parts to 100 parts of water)

You could also find directions for higher dilutions of the chemicals, especially for the Solution B. The results are similar, what changes is the contrasts and the time of exposure, given the same negative. The doses don’t necessarily have to be all that accurate.

The two solutions are prepared separately and set aside to mature for 24 hours before using them.

Paper sensitization has to be made with even doses of solutions A and B, which have to be mixed only right before the use (using them), because the compound is unstable and it would quickly precipitate the Prussian blue (the final compound of the oxidation-reduction activated by light) but most important it would become the ideal environment for moulds that could grow relatively fast. You can sensitize the paper applying the solution with a brush. To get a more extended tone range it would be preferable to apply two coats of sensitizing solution, drying between one coat and the proceeding. Use a hair dryer on a low setting on the back of the paper.

The development has to be made in distilled water. A suggestion to amplify the tone range is to acidify the developing water with 1% citric acid or acetic acid. The absolute best option is to acidify with 1% nitric acid. After development, you have to wash the print under running water for 20-30 minutes.

In the last decades Mike Ware has developed a variation which uses ferric ammonium oxalate and potassium ferricyanide salts. The result is convenient because you obtain: a stable solution (stabilizer ammonium dichromate) which requires a shorter time of exposure, a better tone’s differentiation especially for highlights and dark shadows, therefore increasing the final density of the image and reducing “burning” which required a more careful development in the case of an acidic bath instead of simple water. Unfortunately there is a disadvantage, the final solution chemical reconstitution will in some way (modestly) be more complicated. If you chooses to start experimenting with this work, you can use the pre-dosed kit that you will find on the products list.

To get started with Cyanotype, it is convenient to first try the traditional method (with which you could obtain wonderful results) focusing more on the printing process than on the chemical issues, and maybe later proceed with the “new” method.

We will soon introduce specific kits to tone the cyanotypes in order to obtain other interesting works.

Chemical products used in this procedure are to be considered toxic and non-suitable for human or animal consumption. As a user you must be aware of the risks and take care to protect the environment. Never dispose of chemical waste in a domestic sewage or with common garbage. For a correct disposal please see your local disposal laws.

Ziatype beginners kit

Ziatype Ziatype Beginner kit (Kit09) Kit contents Sensitizing: Ammonium Ferric Oxalate sol.A 25ml Ammonium Ferric Oxalate contrast sol.B

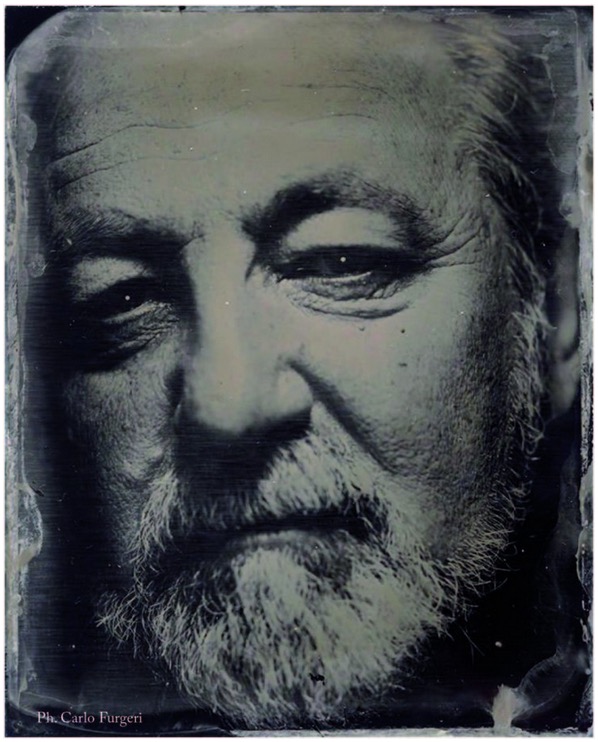

Wet plate Collodion-formulating Poe Boy

Collodion process-Poe Boy formula (No ether/No cadmium) The procedure for the collodion “poe boy”, or “poor boy” as some say, is interesting for it does

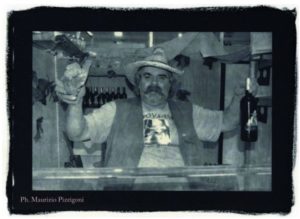

Wet plate Collodion-Old Work-Horse process

Old Work-Horse for positive process 1°- Collodion solution (part A) pour 220 ml plain collodion into a 500 ml beaker slowly, add 140 ml ether